A hybrid machine for the additive manufacturing of large parts – up to 5 m – at optimised costs.

A flexible and agile hybrid industrial cell for manufacturing, adding functions, repairing or rebuilding large parts. A wide range of materials are compatible with the machine, including super alloys, stainless steel, steel and titanium.

Get to know the PAMPROD product description.

Why choose Pamprod?

Compliant parts from the first production run.

→ Quality control

→ Traceable results

→ Controlled raw materials

→ Logistical efficiency

→ Production of XXL-sized parts using Additive Manufacturing

→ Robotic and automated hybrid technologies

→ Innovation in the market

→ ROI

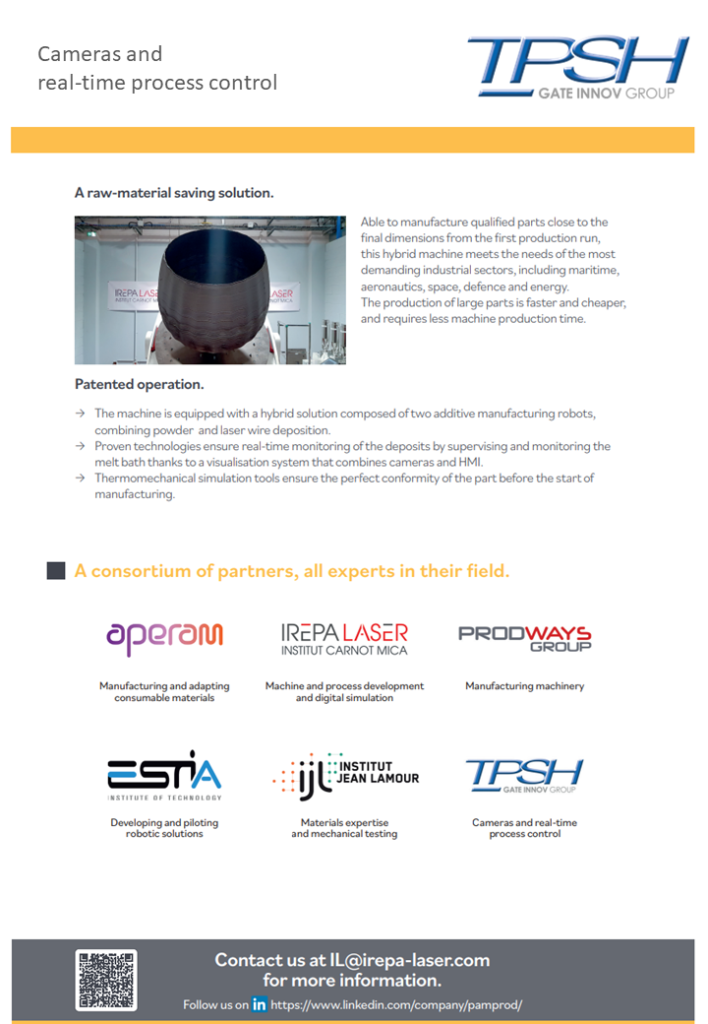

A raw-material saving solution

Able to manufacture qualified parts close to the final dimensions from the first production run, this hybrid machine meets the needs of the most demanding industrial sectors, including maritime, aeronautics, space, defence and energy. The production of large parts is faster and cheaper, and requires less machine production time.

Patented operation.

→ The machine is equipped with a hybrid solution composed of two additive manufacturing robots, combining powder and laser wire deposition.

→ Proven technologies ensure real-time monitoring of the deposits by supervising and monitoring the melt bath thanks to a visualisation system that combines cameras and HMI.

→ Thermomechanical simulation tools ensure the perfect conformity of the part before the start of manufacturing.

A consortium of partners, all experts in their field:

→ APERAM : Manufacturing and adapting consumable materials

→ IREPA LASER : Machine and process development and digital simulation

→ PRODWAYS GROUP : Manufacturing machinery

→ ESTIA : Developing and piloting robotic solutions

→ INSTITUT JEAN LAMOUR : Materials expertise and mechanical testing

→ And us TPSH : Cameras and real-time process control

Download the new brochure of the hybrid machine PAMPROD

For more information, ask us for technical information by email at: IL@irepa-laser.com or info@tpsh.fr or by phone at +331 69 11 91 91. Find all the news and follow the news on Linkedin