Software & Industrial Engineering

OUR SKILLS TO SERVE YOUR TECHNOLOGICAL ADVANCEMENTS.

Our multidisciplinary team will support you in your changes of quality control processes.

We will be able to realize your automation projects around the control phases of simple or complex parts in the following fields combining our competences.Our objective is to automate control and machining processes. The goals are: time saving, uncertainty reduction, repeatability improvement, and controls traceability.

We design special machines specifically for integration on production or assembly line.

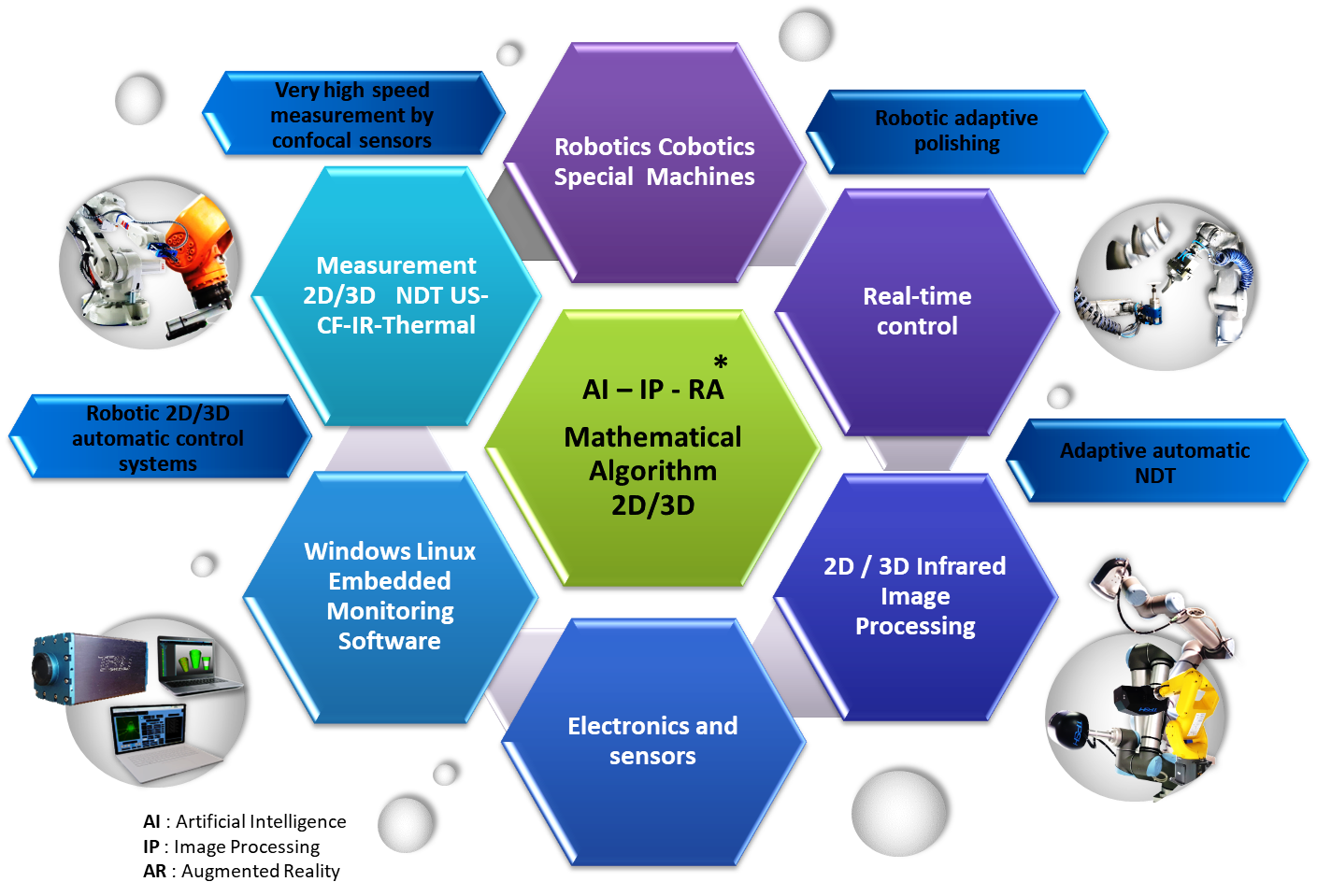

You will find below, the list of our technological bricks :

- Automatic adaptive NDT

- Automatic 2D/3D robotic or cobotized control system

- Adaptive robotic polishing

- Very high speed measurement by confocal or laser sensors

Thanks to our skills in 3D measurement, NDT and robotics, we develop several systems:

- Control of the melting during the additive manufacturing or welding process

- Complex assembly control

- Control of surface roughness

- Contactless measurement for 3D design (CAD comparison included)

- Simulation and real-time computation

Adaptive Machining Processes:

- Welding

- Turning

- Milling

- Grinding

- Polishing

- Deburring

Control and assistance for assembly:

- Assembly assistance with video projection

- Variable parts assembly control

We integrate and combine different technologies in order to specifically meet our customer’s needs:

- Optical: visible and IR cameras, confocal sensors, stereovision

- Ultra sonic

- Eddy Current

- X-ray

- Terahertz radiation

We carry out the software, electronic and robotic developments for the provision and delivery of turnkey machines and solutions.

- Contactless measurement machine

- Complex assembly control

Download more information here PDF

You can also contact us by phone at +33 (0)1 69 11 91 91 or by e-mail at: info@tpsh.fr

Photos 2022 – TPSH ©