WE ACCOMPANY YOU DURING THE PHASES OF FEASIBILITY STUDY IN INDUSTRIALIZATION OF 2D/3D CONTROL.

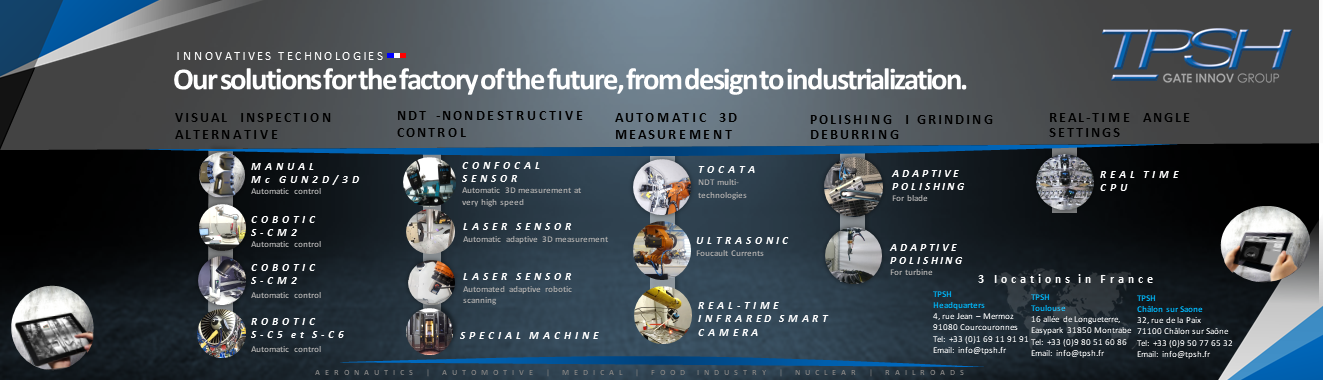

We offer you alternative solutions to binocular inspection, visual and radiographic inspection of welds and additive manufacturing to enable you to improve the conformity of your products, in support of the operators by a systematic final inspection on the production or assembly lines.

Entrust us with your technological innovation projects and your technical progress.

Our skills are in 2D and 3D automatic control, automatic non-destructive testing systems, adaptive process machines (grinding, polishing, deburring, welding), robotized high speed measurement, associated with Artificial Intelligence for automatic real time decision making.