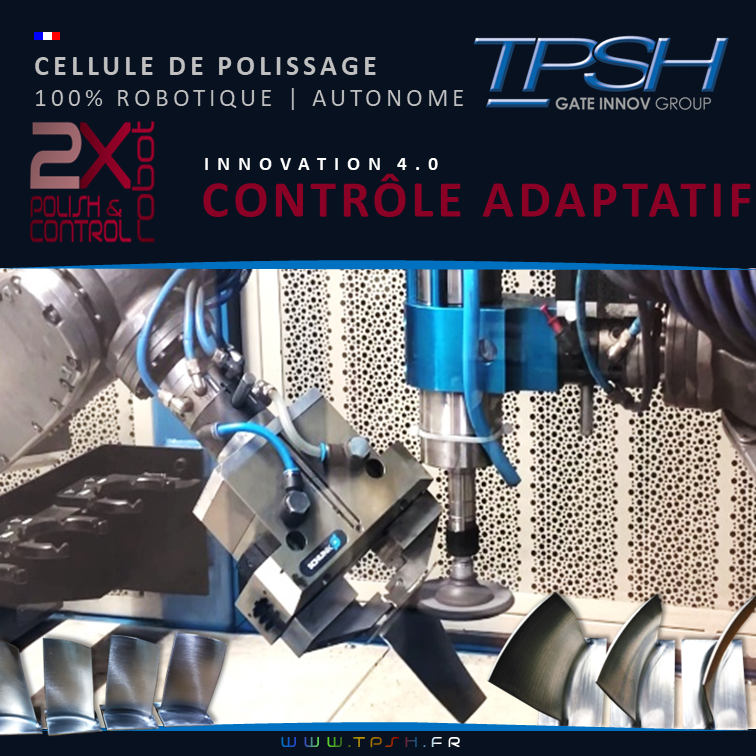

ROBOTIC AND AUTOMATIC POLISHING SYSTEM FOR BLADE FINISH

A NEW TECHNOLOGY: SOLUTION OF ADAPTIVE PROCESSES.

A 100% AUTOMATED AND ROBOTIC SYSTEM FOR BLADE AND TURBINE.

We have designed an automated adaptive process technology for part finishing. Our robotic polishing and grinding cell combines a measurement system and parameterized trajectories. The objective is to guarantee better productivity and ensure traceability by generating a PV of control and conformity in automatic state of a piece after polishing.

Points to be noted:

- Automatic quantization of the data assigned to the process in order to bring the piece back to the theoretical level

- Monitoring quality of each piece

- Adaptation of the trajectories according to the defects of shape of the parts

- Traceability of conformity reports

- and increase in the rate of production

Download the description of our automatic robotic polishing/deburring cells.