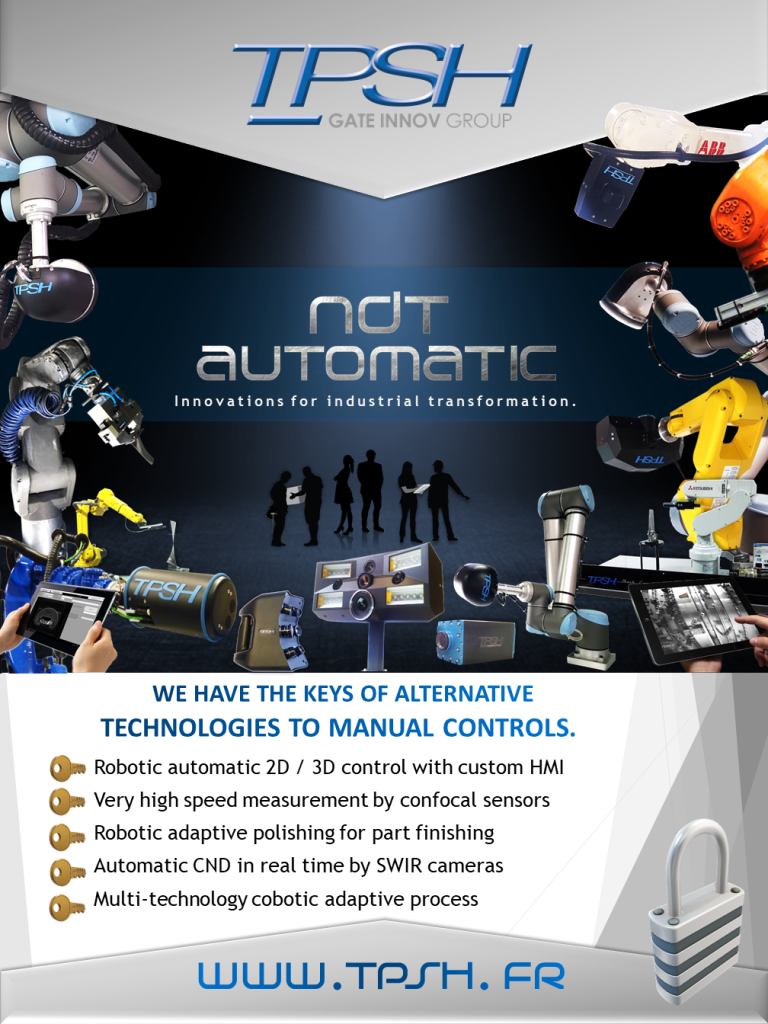

OUR KNOW HOW IN AUTOMATIC NDT

Our innovations for your industrial transformation.

We have the keys of alternative technologies to manual controls :

- Robotic automatic 2D/3D control and custom HMI

- Robotic adaptive polishing for part finishing

- Automatic NDT in real time by SWIR camera

- Multi-technology cobotic measurement/control process

- Very high speed measurement by confocal sensors

We will be responding to your automatic detection projects on your production lines. Don’t hesitate to contact us to discuss your issues.

Our team is available by phone at +33(1) 69 11 91 91 or by email: info@tpsh.fr

Remember, TPSH is a French company based in the Ile de France(91), in chalon-sur-Saône (71) and Toulouse(31).

We are specialized in 2D/3D measurement with and without contact, metrology, non descrutive testing, adaptive processes in real time since 1990.

The combination of our skills in robotics, cobotics, mechanics, computer science electronics and optics allow us to offer to large industrial company of technological and innovative solutions.

Our office of study and adivces ensures an integral project follow-up of feasibility study to the realization of the product until the industrial launch for needs of controls of complex assemblies, réductions or deletions of some manual tasks.