TPSH, partner in the PAMPROD project: ADDITIVE MANUFACTURING PROCESSES.

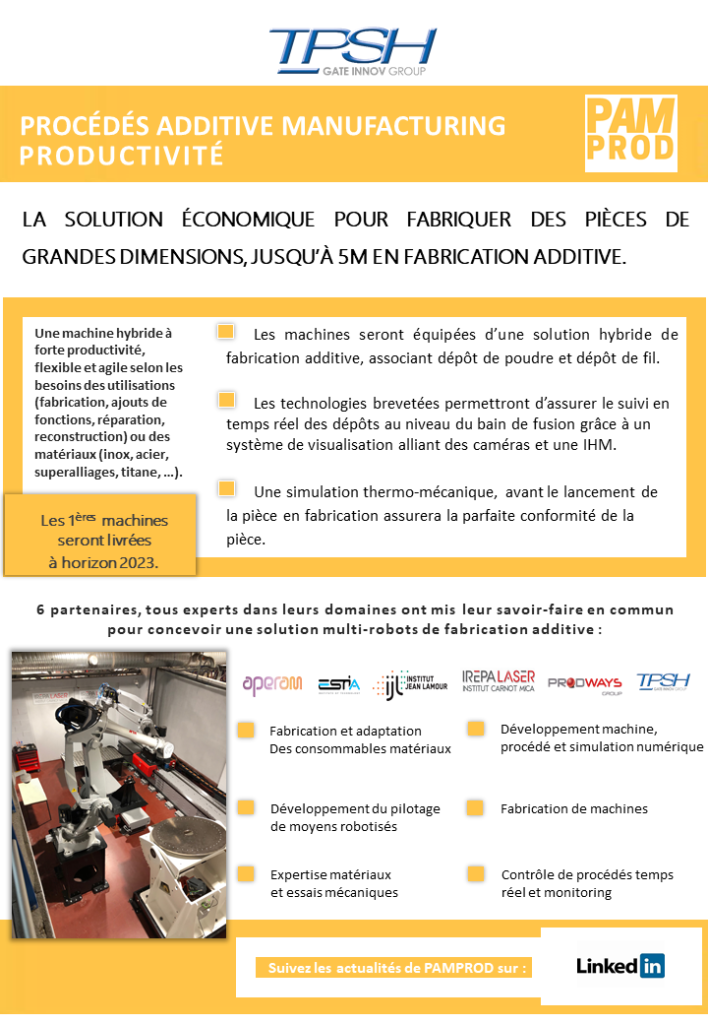

A hybrid machine with high productivity, flexible and agile according to the needs of uses (manufacturing, addition of functions, repair, reconstruction) or materials (stainless steel, steel, superalloys, titanium, …).

Innovations in this process:

- The machines are equipped with a hybrid additive manufacturing solution, combining powder and wire deposition.

- The patented technologies allow for real time monitoring of the deposits in the melt bath using a visualization system combining cameras and a HMI.

- A thermo-mechanical simulation, before the part is launched in production, ensures the perfect conformity of the part.

6 partners, all experts in their expertises, have combined their know-how to design a multi-robot solution for additive manufacturing: :

• Aperam (Manufacturing and adaptation of material consumables)

• Estia (Piloting of robotics)

• Institut Jean Lamour (m+Materials expertise and mechanical testing)

• IREPA LASER (Machine and process development and numerical simulation)

• Prodways (Machine manufacturing)

• TPSH (system monitoring and smart camera)

Follow the news on LinkedIn hereLinkedIn ici “and ask any questions about it.