100% automatic quality control that combines speed, cost and deep learning algorithms

The use of AI has been growing across the industrial automation space for several years now. By 2035, AI-powered technologies could inscrease labor productivité by up to 40% in manufacturing.

One application with a big potential to benefit from AI is quality control based on video analytics. This technology is called cutomatic optical inspection and it improves quality control in terms of speed, latency and costs. It is a completely automated and cobotic process based on deep learning algorithms that have been trained to recognize specific elements on a product.

A simple and intuitive process.

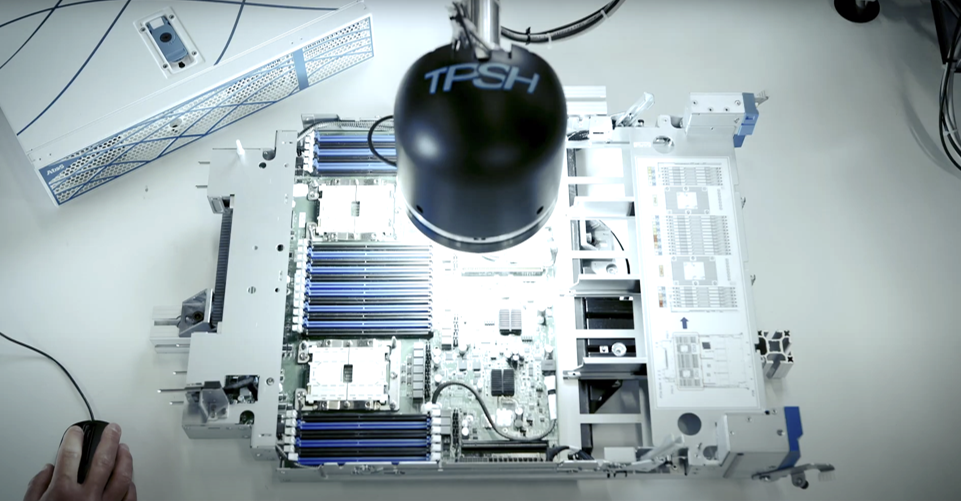

This video examines the process to detect faults on a circuit board based on computer vision. The operator monitors the process on a desktop application and selects the right program with pre-selected parameters. These parameters include different elemets like the positioning of cables, the cleanliness of memory slots, the presence of CPU protection and defects on the panel, the presence of capacitors, USB plugs and screws and the series and article code. Then, the operator launches the operations. The automatic cobot begins to move to a position above the circuit board, emitting a sequence of flashes as it moves. Each flash captures a picture which is stored as data. This data is transmitted in real time to the BullSequena Edge serveur (Atos) which processes the data.

Powerful artificial intelligence algorithms are developed by TPSH doctors in image processing.

These quality control algorithms are unique for each product. After one minute, the session is over and the cobot retracts. At the end of the analysis process, the results are collected in the report. The report summarizes any defects and the conformiy of the different elements examined. The entire operation is carried out in an industrial environment offering a flexible, quick and efficient quality control process to any industry.

Summary of control steps:

- Step 1 : Monitoring application configuration

- Step 2 : Play the quality control

- Step 3 : Image generation & data processing

- Step 4 : Report generation

Ask us for more technical information by mail : info@tpsh.fr or by phone +331 69 11 91 91