IMPROVE YOUR INSPECTION, MEASUREMENT, NDT, AND ADAPTIVE PROCESSES WITH OUR TECHNOLOGY PRODUCT .

TPSH offers you several technologies for automatec quality inspection by robotic, cobotic, fixes, transportable or on AGV systems.

| Designations: | Industrial challenges: | Leasing: |

1st HAND-HELD 3D MEASUREMENT TOOL FOR MANUAL QUALITY INSPECTION:

|

- Automatic manual quality inspection - Improve traceability of deliverables - Reduce exported non-quality - Improve predictive maintenance - Digitise processes |

Included in the contract: - 3DMcGUN - Integrated monitoring station - Interventions - Spare parts - Types of results:  Ask us about the monthly cost over 5 years. |

| Designations: | Industrial challenges: | Leasing: |

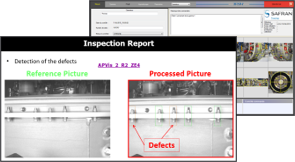

QUALITY INSPECTION CELL FOR COMPLEX ASSEMBLY CONTROL:

|

- Automatic quality inspection - Improve traceability of deliverables - Reduce exported non-quality - Reduce the difficulty of certain tasks - Adapt processes in real time - Improve predictive maintenance - Digitise processes |

Includes in the contract: - Measuring cell (robot, electrical cabinet, measuring head, immaterial scanners) - Supervision station - Interventions - Spare parts - Types of results :  Ask us about the monthly cost over 5 years. |

| Designations: | Industrial challenges: | Leasing: |

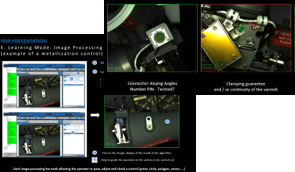

INDUSTRIAL MOBILE WORKSTATION – COBOTIC INSPECTION FOR QUALITY CONTROL:

|

- Automatic quality inspection - lmprove traceability of products - Reduce exported non-quality - Adapt processes in real time - Improve predictive maintenance - Digitise processes - Optimise factory layout |

Includes in the contract: - 1 control workstation (electrical cabinet, measuring head, turntable, safety) - Supervision station - Interventions - Spare parts - (except cobot)- Types of results:  Ask us about the monthly cost over 5 years. |

| Designations : | Industrial challenges: | Leasing: |

AUTOMATIC OPTICAL CELL FOR QUALITY CONTROL OF FINISHED PRODUCTS: Our cobotic NDT technology for the detection of assembly defects is the fusion between an intelligent optical inspection head and a cobot with: |

- Automatic quality inspection - Improve traceability of deliverables - Reduce exported non-quality - Adapt processes in real time - Improve predictive maintenance - Digitise processes - Control cycle of 6 simultaneous parts |

Includes in the contract: - Measuring cell (cobot, electrical cabinet, measuring head, immaterial scanners, 6 rotary tables) - Supervision station - Interventions - Spare parts-Types of results:  Ask us about the monthly cost over 5 years. |

| Designations : | Industrial challenge: | Leasing: |

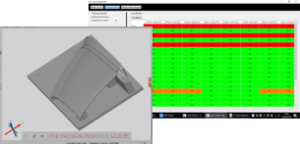

1st HYBRID 3D MEASURING SYSTEM WITH CONFOCAL SENSOR AND LASER LINE :

|

- Automatic quality inspection - Reduce exported non-quality - Adapt processes in real time - Improve predictive maintenance - Digitise processes - Synchronisation of robots |

Includes in the contract: - 3D measurement head - Electrical cabinet - Supervision station - Interventions - Spare parts-Types of results:  Ask us about the monthly cost over 5 years. |

| Designations : | Industrial challenges: | Leasing: |

1st 3D MEASURING SYSTEM WITH CONFOCAL SENSOR: Our technology is a high speed robotic system that allows to detect both sides of the same glass at the same time and to detect air gap defects in laminated glass: |

- 100% production control - Automatic robotic quality inspection - Reduce exported non-quality - Adapt processes in real time - Improve predictive maintenance - Digitise processes |

Includes in the contract: - 3D measurement head - Electrical cabinet - Supervision station - Interventions - Spare parts -Types of results:  Ask us about the monthly cost over 5 years |

For more information, ask us for technical information by email: info@tpsh.fr or by phone +331 69 11 91 91.