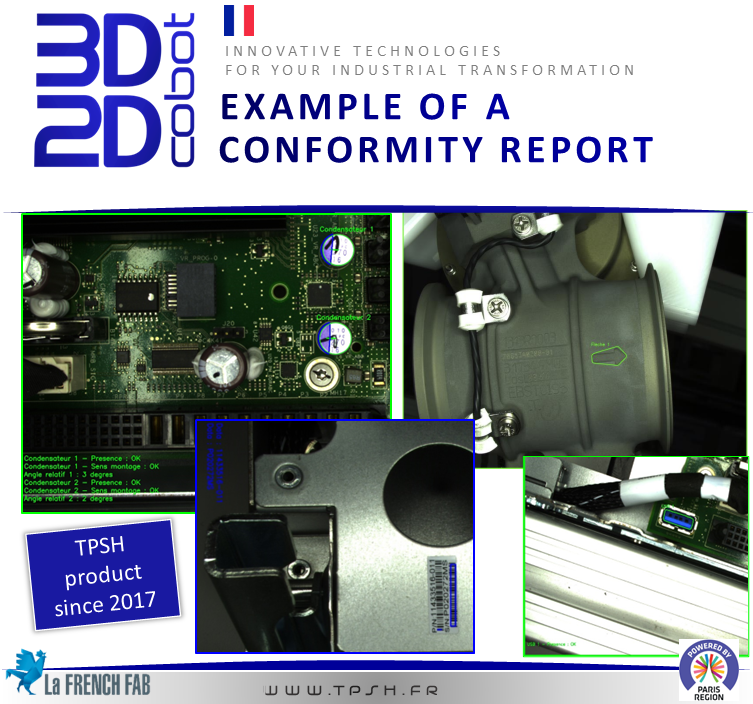

COBOTIC INSPECTION: MOBILE OR FIXED 3D MEASUREMENT SYSTEM.

A TPSH – 100% automatic solution for quality control.

TPSH, a forerunner for more than 15 years in Industry 4.0 technologies, has developed a 2D/3D automatic industrial control technology for the compliance of complex assemblies meeting the needs of Industry 5.0.

This new cobotic system is a mobile, easily transportable and versatile inspection workstation, equipped with a cobot interfaced with a TPSH intelligent measuring head and a HMI to supervise all inspection cycles to ensure traceability of results and reduce exported non-quality.

A 100% autonomous and automatic control system including:

- 1 workstation of 1m x 1.50m mobile or static according to the implantations

- 1 cobot

- 1 rotary table

- 1 calibration tool for the part to be controlled

- 1 supervision PC with a customizable and intuitive HMI

- 1 safety system

- 1 intelligent head for 2D and 3D control equipped with :

-> 1 camera

->1 angular lighting

->1 laser pointer for image acquisition

A 2D | 3D NDT detection system to:

- Reduce significantly the errors on complex assemblies

- Improve defect analysis and characterization processes

- Reduce costs associated with non-quality

- Optimize human resources

- Process information in real time in the TPSH supervisor using algorithms developed by TPSH

A technology associated with Artificial Intelligence and the Cloud that:

- Improves the quality of deliverables and increases competitiveness

- Quickly perform assembly, dimensional and geometric checks

- Facilitates integration into the production or control chain

- Brings robustness and reliability to the inspection process

See one of the videos of the system in an industrial setting: https://www.youtube.com/watch?v=0OJGHuz37ZY

For more information, ask us about the monthly cost by email: info@tpsh.fr or by phone: 033 1 69 11 91 91.