|

1st HANDY TOOL FOR 3D MEASUREMENT FOR MANUAL QUALITY INSPECTION:

3D Mc GUN© is the new portable metrology control system designed to detect:

> Control of rivet assembly,

> Control of aspect defects (peaks, impacts, scratches, flaking),

> Assembly control and analysis of sinking and deformation,

|

|

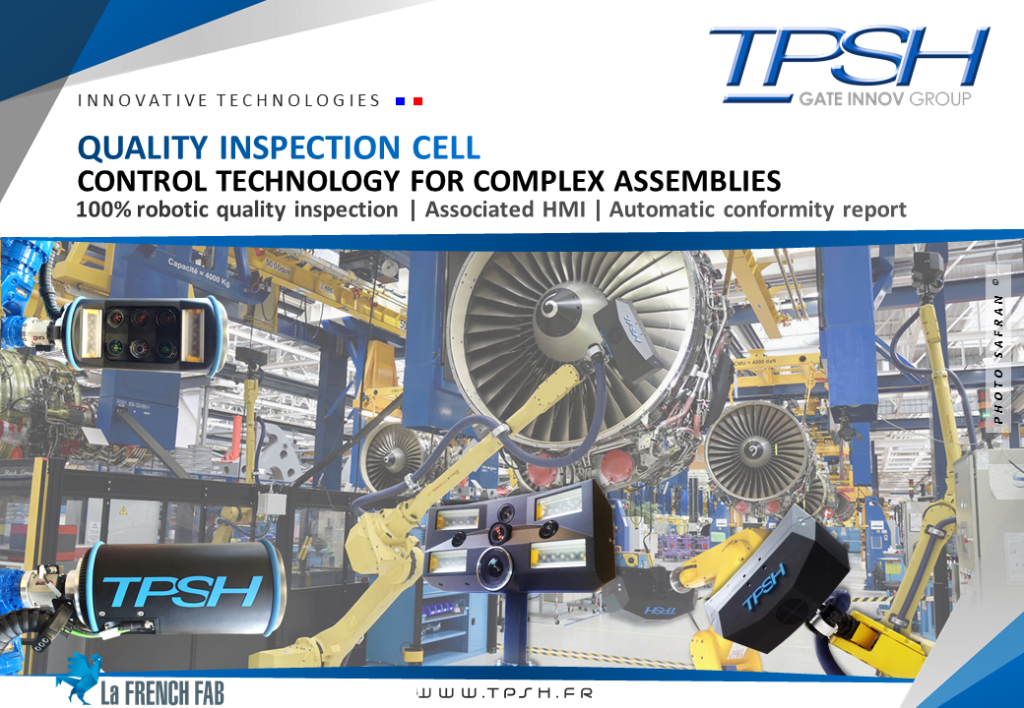

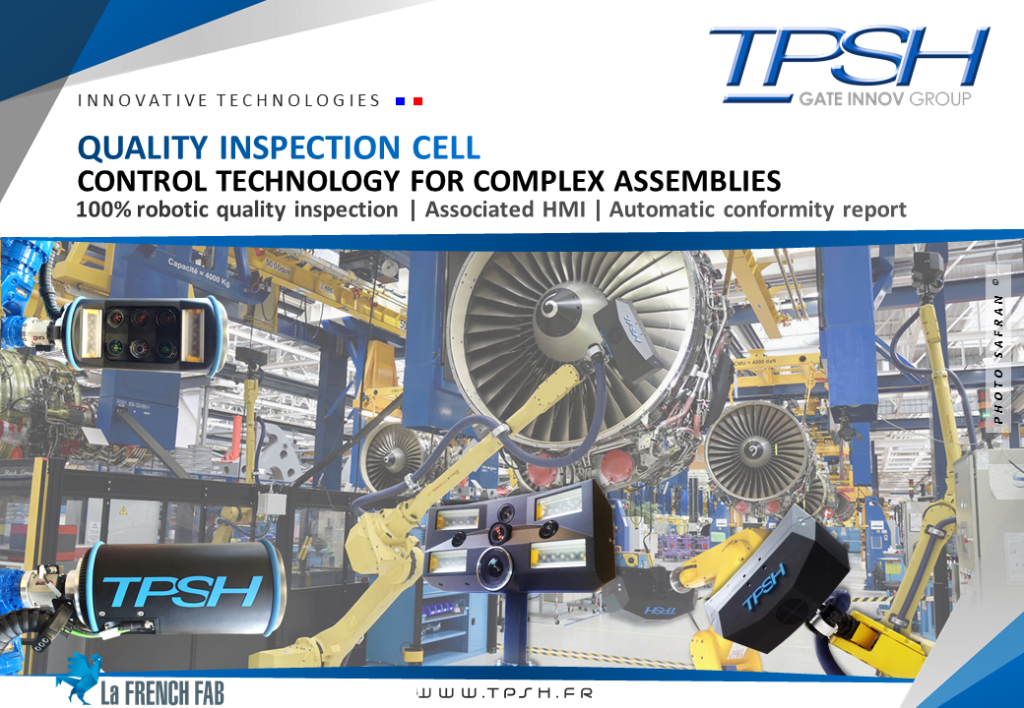

QUALITY INSPECTION CELL FOR THE CONTROL OF COMPLEX ASSEMBLIES:

100% automatic, autonomous and robotised technology for the control of complex assemblies with:

> 2D/3D control by vision (presence, shape, color,direction…),

> Multi-element control (Fittings, connectors, nuts, screws, brake wire, piping, seals, scratches, chipping, paint defects, etc…),

> Associated HMI that issues a conformity report,

|

|

INDUSTRIAL MOBILE WORKBENCH COBOTIC INSPECTION FOR QUALITY CONTROL:

Our new cobotic system is a transportable, versatile workbench that reduces the non-quality exported with:

> A cobot interfaced with an intelligent TPSH control and measurement head,

> An HMI to supervise all the control cycles and check the traceability of the results,

> 100% automatic and autonomous,

|

|

|

|

OPTICAL AUTOMATIC CELL FOR QUALITY CONTROL OF FINISHED PRODUCTS:

Our cobotic NDT technology for the detection of assembly defects is the fusion between an smart otpical inspection head and a cobot with:

> An inspection station with up to 6 rotary tables and their tools,

> A tool for creating inspection ranges,

> And allows statisctical analysis of the results,

|

|

|

|

1st HYBRID 3D MEASUREMENT SYSTEM WITH CONFOCAL SENSOR AND LASER LINE:

New very high speed robotised turnkey system for the in-line control of 100% of the production (4 to 12m/s) to:

> To analyse the dimensional, geometrical and shape conformity of industrial products with a mix of opaque and transparent multi-materials (“glass, metal”, “glass, plastic”),

> To reduce exported no-quality,

> And allows the statistical analysis of the results,

|

|

|

|

1st 3D MEASUREMENT SYSTEM WITH CONFOCAL SENSOR:

Our technology is a system that allows us to measure both sides of the same glass at the same time, and to detect air gap defects in laminated glass:

> Working distance 50mm,

> Overall repeatability of the measurement chain (robot + sensor) +/-50µm,(tip, impacts, scratches, flaking),

> Development of a calibration model applicable to industrial robots,

|

|

|

|

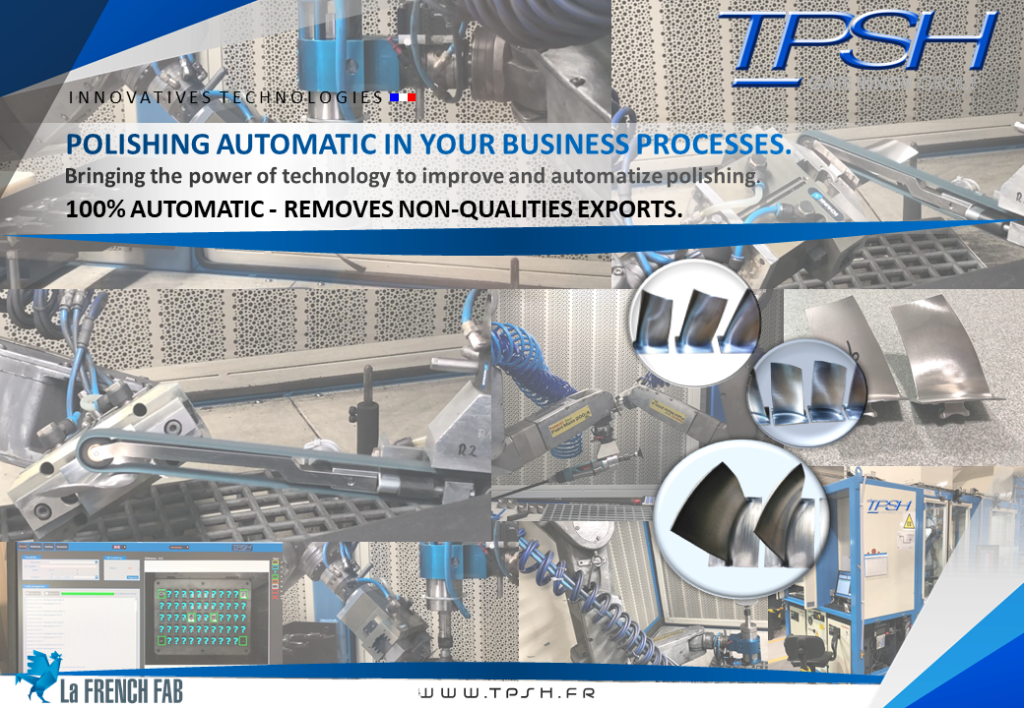

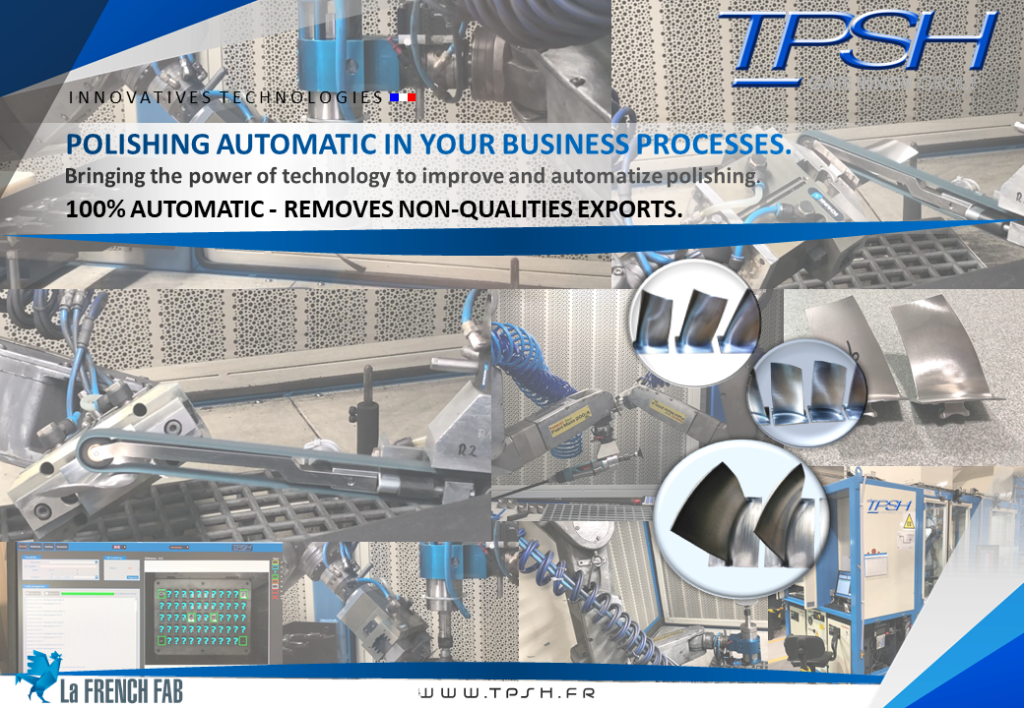

ROBOTIC CELL FOR BLADE & TURBINE FINISHING – 100% AUTOMATIC:

Our robotic polishing, grinding and deburring cell combines a 2D/3D measurement system with adaptive processes and dedicated PHL-AA trajectories:

> Blades: BA/BF, vein, Extrados/intrados, vein radys, gendarme hats, etc,

> Turbines: BA/BF, vein, Extrados/intrados, vein radius, flange, flange holes, etc,

> Coupled with our cycle supervision HMI for statistical analysis and monitoring of the results obtained,

|

|

|

|

ADAPTIVE ULTRASONIC MEASUREMENT CELL:

Scanning of the surface and calculation of corrections for control – real time:

> Integration of one measurement head with a 3D measurement line laser + an ultrasound sensor

> Merging of PHL software to create 3d control programs automatically,

> 3D and NDT inspection coupled in real-time,

|

|

|

|

TCAM128-65 |REAL-TIME PROCESS CONTROL CAMERA:

SMART infrared camera, the TCAM128-65 allows to control in real time the physical parameters of a melt bath to:

> YAG, TIG, MIG, MAG,– LASER, FSW welding,

> LM et DMD additive manufacturing,

> Real-time NDT in the process,

|

|

HMI – HUMAN MACHINE INTERFACE – REAL-TIME CONTROL SYNCHRONISED TO ROBOTS AND COBOTS:

We develop our supervision software (Windows, Linux) integrated into all our products, control applications and measurement cells:

> 100% automatic and customisable,

> With many innovative functions,

> Autonomous and for operators,

|

| « Technological innovation in the service of industry since 1990. » |

|

|

We are at your service for any questions you may have.

Find us on 3 sites in France: Evry-Courcouronnes | Chalon-sur-Saône | Toulouse

TPSH – Evry- Courcouronnes

Head office

4 rue Jean-Mermoz

91080 EVRY -COURCOURONNES

+33(0)1 69 11 91 91 |

TPSH – Chalon-sur-Saône

Office

32, rue de la Paix

71100 CHALON SUR SAONE

+33(0) 9 50 77 65 32 |

TPSH – Toulouse

Office

16 allée de Longueterre – Easypark

31850 MONTRABE – TOULOUSE

+33(0) 9 80 51 60 86 |

|