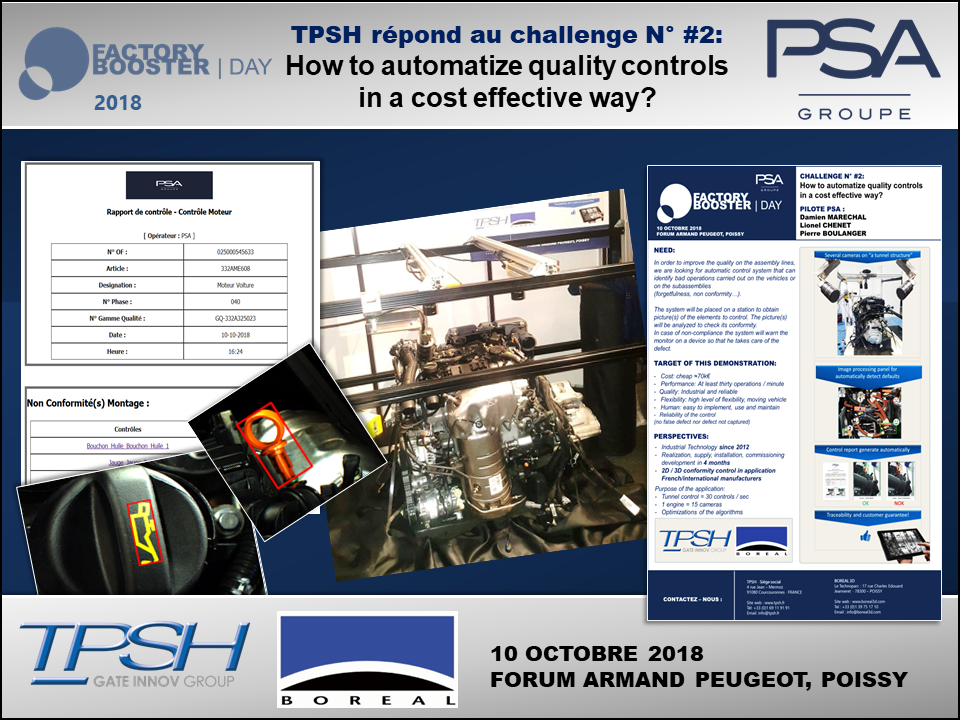

OUR DECTECTION SYSTEM FOR THE CHALLENGE N°#2 : How to automatize quality controls in a cost effective way?

PSA NEED:

In order to improve the quality on the assembly lines, PSA are looking for a automatic contrôle system that can identify bad operations carried out on the vehicules or on the suassemblies ( forgetfulness, no conformity…).

The system will be placed on a station to obtain picture(s) of the elements to control. The picture(s) will be analyzed to check its conformity.

In case of non-compliance the system will warm the monitor on a device so that he takes care of the defect.

TARGET OF THIS DEMONSTRATION:

- Performance: at least thirty operations/minute

- Quality: industrial and reliable

- Flexibility: high level of flexibility, Moving vehicle

- Human: easy to implement, use and maintain

- Reliability of the control (no false defect or defect not captured)

PERPECTIVES:

- Industrial Technology since 2012

- Realization, supply, installation, commissioning development in 4 months

-2D/3D conformity controls in application French/international manufacturers

Purpose of this application:

- 1 tunnel control =30 controls/sec

- 1 engine = 15 cameras

- Optimizations of the algorithms