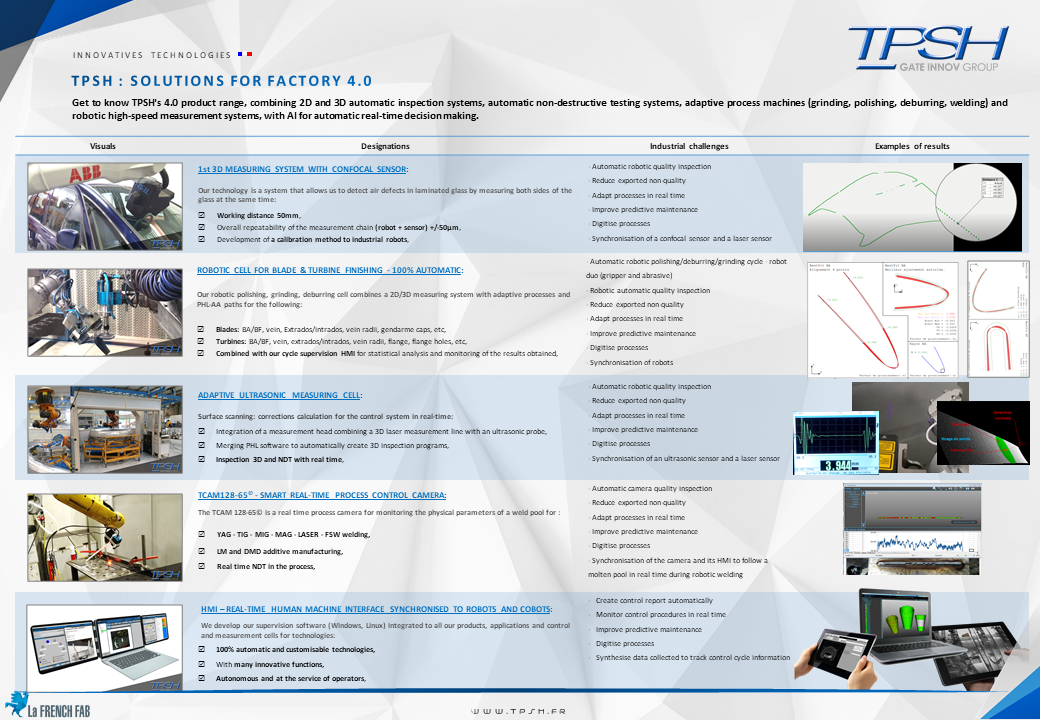

Get to know TPSH’s 4.0 product range, combining 2D and 3D automatic inspection systems, automatic non-destructive testing systems, adaptive process machines (grinding, polishing, deburring, welding) and high-speed robotic measurement systems, combined with AI for automatic real-time decision making.

1st 3D MEASUREMENT SYSTEM WITH CONFOCAL SENSOR:

Our technology is a system that allows to detect air defects in laminated glass by measuring both sides of the glass at the same time:

- Working distance 50mm,

- Overall repeatability of the measurement chain (robot + sensor) +/-50µm,

- Development of a calibration principle applicable to industrial robots,

ROBOTIC CELL FOR BLADE & TURBINE FINISHING – 100% AUTOMATIC:

Our robotic polishing, grinding, deburring cell combines a 2D/3D measuring system with adaptive processes and PHL-AA paths for:

- Blades : BA/BF, vein, Extrados/intrados, rays vein, policeman’s hats, etc…,

- Turbines : BA/BF, vein, Extrados/intrados, rays vein, flange, flange holes, etc…,

- Combined with our cycle supervision HMI for statistical analysis and monitoring of the results obtained,

ADAPTATIVE ULTRASONIC MEASURING CELL:

surface scanning: corrections calculation for the control system in real-time:

- Integration of a measurement head combining a 3D laser measurement line with an ultrasonic probe,

- Merging PHL software to automatically create 3D inspection programs,

- Inspection 3D and NDT with real-time,

TCAM128-65©- SMART REAL-TIME PROCESS CONTROL CAMERA:

The TCAM 128-65© is a real time camera for monitoring the physical parameters of a weld pool for:

- YAG – TIG – MIG – MAG – LASER – FSW welding,

- LM and DMD additive manufacturing,

- Real time NDT in the process,

HMI – REAL-TIME HUMAN MACHINE INTERFACE SYNCHRONISED TO ROBOTS AND COBOTS:

We develop our supervision software (Windows, Linux) integrated to all product, applications control and measurement cells for technologies:

- 100% automatic and customisable technologies,

- With many innovation functions,

- Autonomous and at the service of operators,