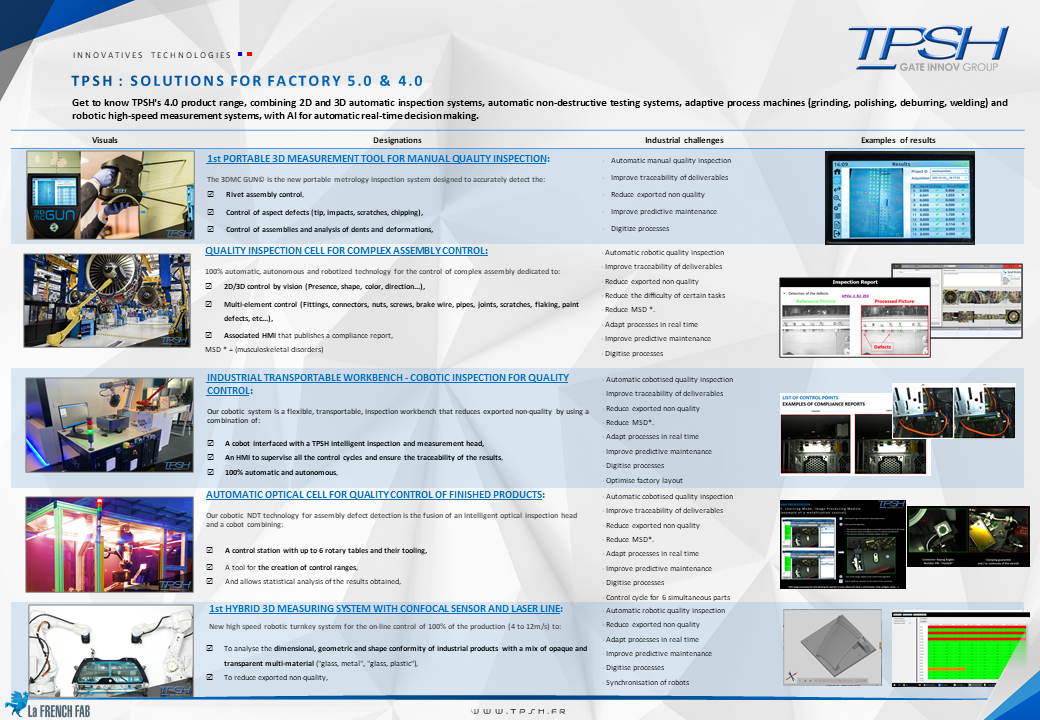

Learn more about TPSH’s 5.0 and 4.0 product range, combining cobotised 2D and 3D automatic inspection systems, automatic non-destructive testing systems, automatic inspection cells, mobile autonomous inspection workbench, combined with AI for automatic real-time decision making.

1st PORTABLE 3D MEASUREMENT TOOL FOR MANUAL QUALITY INSPECTION:

The 3DMC GUN© is the new portable metrology inspection system designed to accurately detect the:

- Rivet assembly control

- Control of aspect defect (tip, impacts, scratches, chipping)

- Control of assemblies and analysis of dents and deformations

QUALITY INSPECTION CELL FOR COMPLEX ASSEMBLY CONTROL:

100% automatic, autonomous and robotized technology for the control of complex assembly dedicated to:

- 2D/3D control by vision ( presence, shape, color, direction)

- Multi-element control ( fittings, connectors, nuts, screws, brake wire, pipes, joints scratches, flaking, paint defects, etc)

- Associated HMI that publishes a compliance report

INDUSTRIAL TRANSPORTABLE WORKBENCH – COBOTIC INSPECTION FOR QUALITY CONTROL:

Our cobotic system is a flexible, transportable, inspection workbench that reduces exported non-quality by using a combination of:

- A cobot interfaced with a TPSH intelligent inspection and measurement head

- An HMI to supervise all the control cycles and ensure the traceability of the result

- 100% automatic and autonomous

AUTOMATIC OPTICAL CELL FOR QUALITY CONTROL OF FINISHED PRODUCTS:

Our cobotic NDT technology for assembly defect detection is the fusion of an intelligent optical inspection head and a cobot combining:

- A control station with up to 6 rotary tables and their tooling

- A tool for the creation of control ranges

- And allows statistical analysis of the results obtained

1st HYBRID 3D MEASURING SYSTEM WITH CONFOCAL SENSOR AND LASER LINEL:

New high speed robotic turnkey system for the on-line control of 100% of the production (4 to 12m/s) to:

- A analyse the dimensional, geometric and shape conformity of industrial produts with a mix of opaque and transparent multi-material ( “glass, metal” – “glass, plactic)

- To reduce exported non-quality

More information on www.tpsh.fr or ask us for technical information by email: info@tpsh.fr