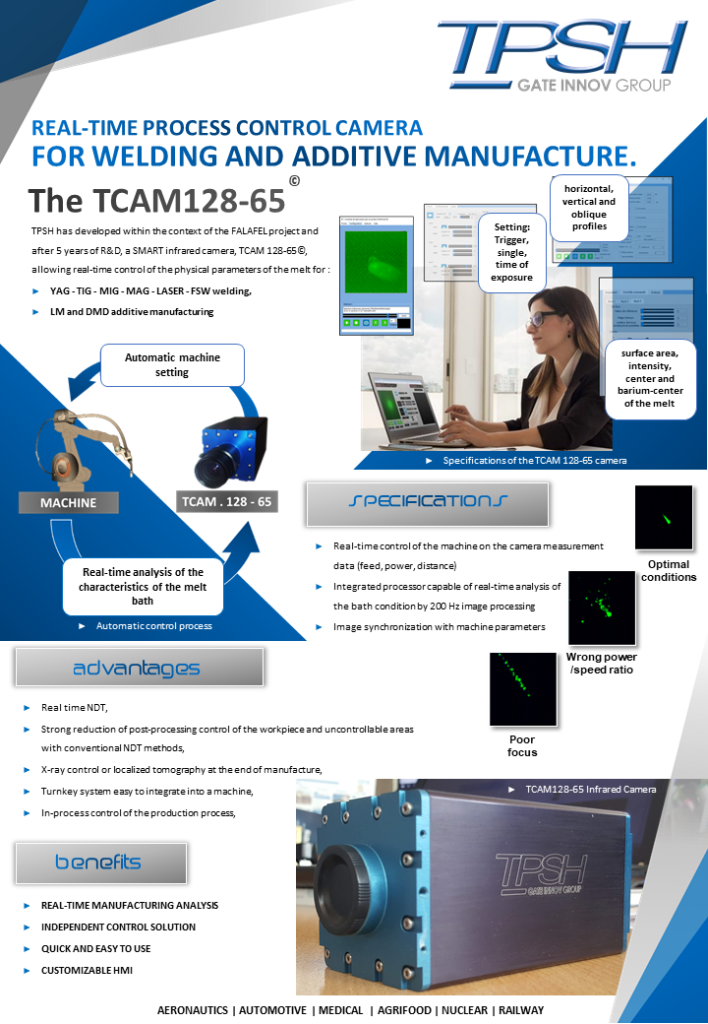

The TCAM128-65 is a real-time process control camera for welding and additive manufacturing.

TPSH has developed within the framework of the FALAFEL project and after 5 years of R&D, a SMART infrared camera, the TCAM 128-65, allowing to control in real time the physical parameters of a melt bath for:

- YAG – TIG – MIG – MAG – LASER – FSW welding

- LM and DMD additive manufacturing

The main characteristics are as follows:

- Real-time control of the machine according to the measurement data of the camera (feed, power and distance),

- Integrated processor able to analyse in real time the state of the bath by image processing at 200Hz,

- Synchronization of images with machine parameters,

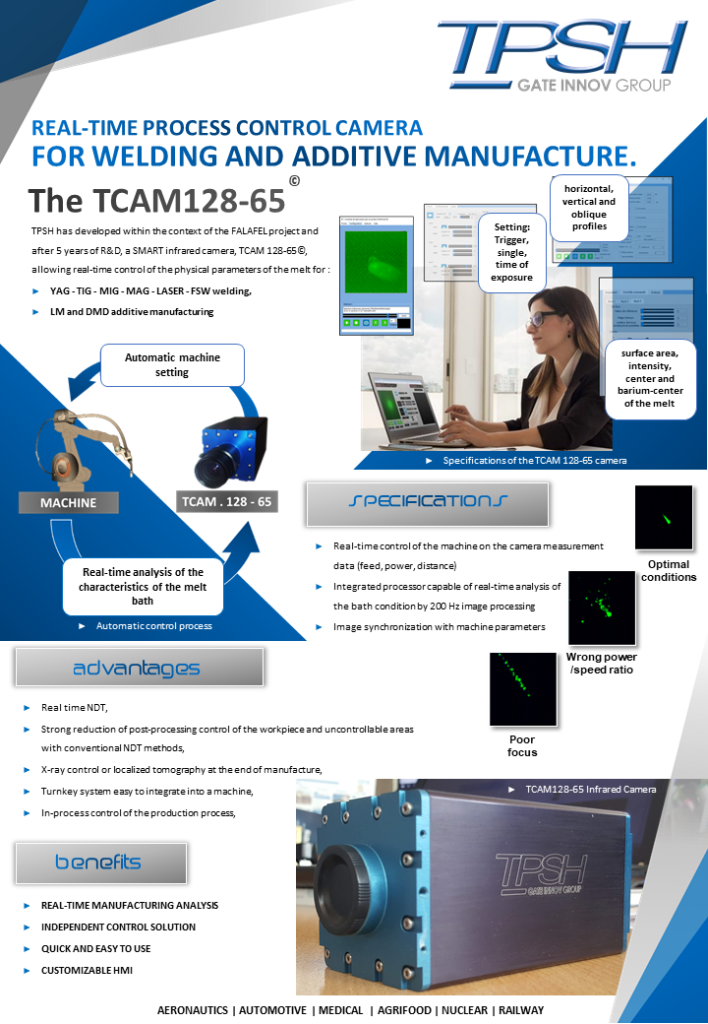

The advantages of TCAM128-65 include the following:

- Real-time NDT in Process,

- Strong reduction of post-processing control of the part and uncontrollable areas with conventional NDT methods,

- X-ray control or localized tomography at the end of the manufacturing process,

- Turnkey system easy to integrate into a machine,

- Control in the production process,

Find the advantages:

- Real-time analysis of manufacturing,

- Stand-alone control solution,

- Quick and easy to use,

- Customizable HMI,

If you have any questions, do not hesitate to contact us by email: info@tpsh.fr or by phone: +331 69 11 91 91.

Back to previous articles.

If you wish to download the brochure of the camera, please click on this link.