TPSH and ATOS will welcome you on the ATOS stand on Thursday 30th January from 8.30 am at the HUMAN TECH DAYS event at the Palais des Congrès of Tours, Le Vinci.

This exhibition dedicated to professionals will be the opportunity to present you the new portable product for the detection of cosmetic defects in automatic associated with the real time processing of collected data.

We invite you to come and exchange with us on the major industrial IoT challenges associated with the innovative technologies of automatic detection, control and measurement of the factory of the tomorrow.

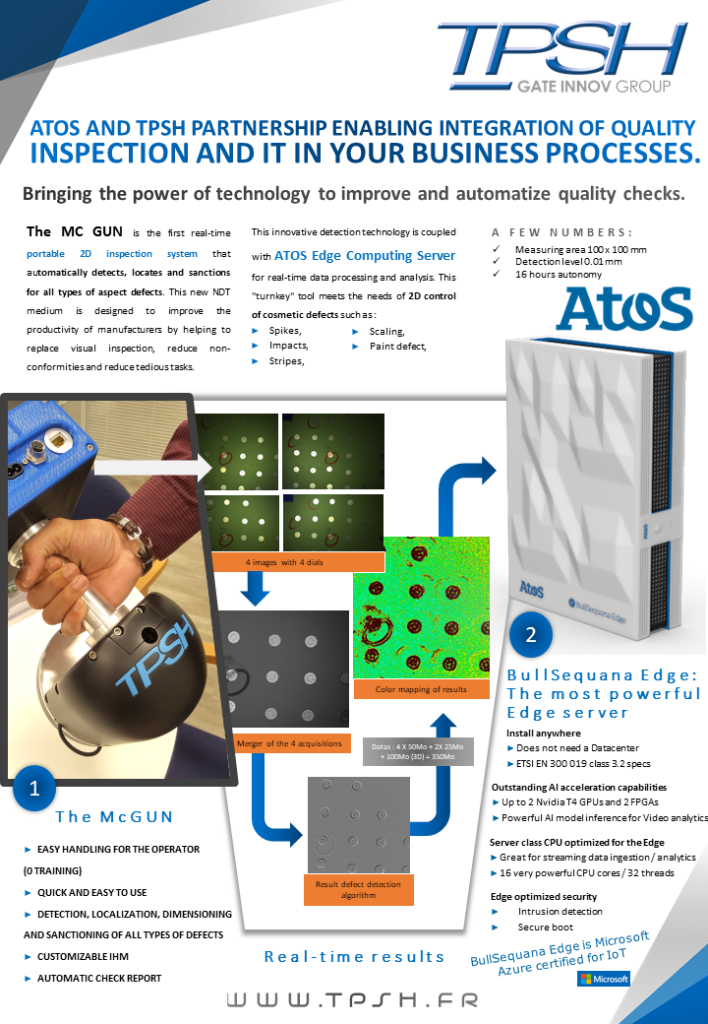

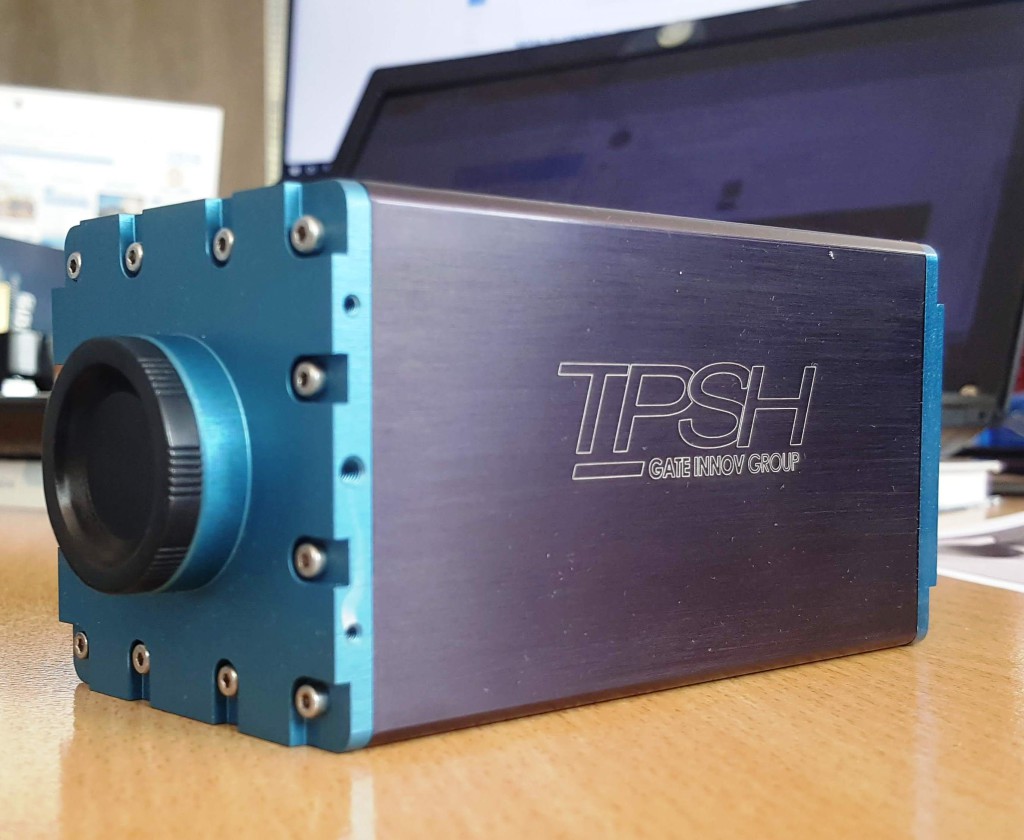

TPSH will be exhibiting its prototype to help replace visual inspection, reduce non-compliance and reduce inconvenience : The Mc GUN. This technology is coupled with Atos Origin’s Edge Computing server for real-time data processing and analysis.

About the McGUN 2D :

The MC GUN is the first real-time portable 2D inspection system that automatically detects, locates and punishes all types of aspect defects. This new NDT medium is designed to improve the productivity of manufacturers by helping to replace visual inspection, reduce non-conformities and reduce inconvenience. This innovative detection technology is coupled with the ATOS Edge Computing server for real-time data processing and analysis. This “turnkey” tool meets the need for 2D control of cosmetic defects such as: spikes, impacts, scratches, flaking, paint defects…

Meet us at: Palais des Congrès of Tours, Le Vinci: 26 Boulevard Heurteloup, 37000 Tours.

Free registration on: https://humantechdays.badge.events/

For more information on the exhibition, go to: https://www.humantechdays.fr/