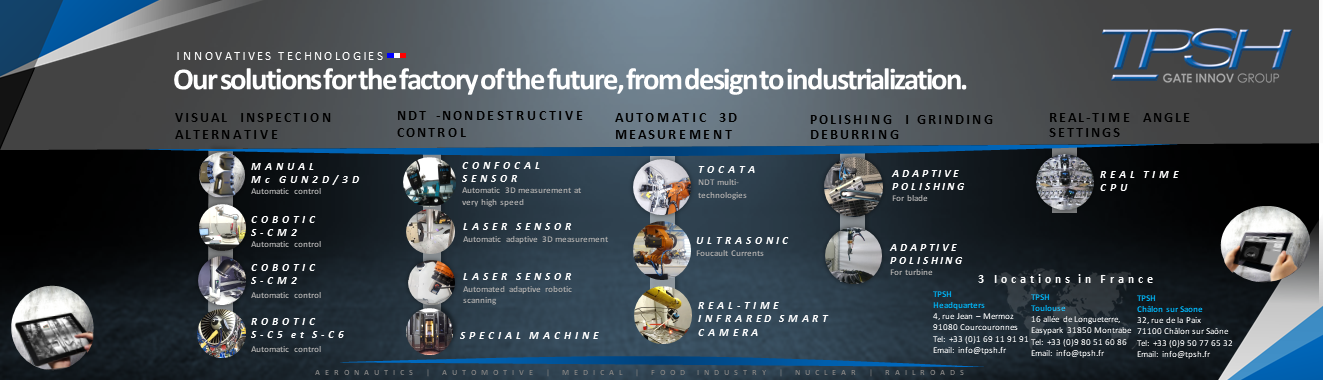

AUTOMATIC CONTROL, ROBOTIZATION, IA, ADAPTIVE PROCESSES, CLOUD, REMOTE CONTROL, TPSH’S 4.0 PRODUCTS AT THE HEART OF THE INDUSTRIAL STAKES RELATED TO THE HEALTH CRISIS.

TPSH invites you to discover its range of products 4.0.

2D AND 3D AUTOMATIC CONTROL SYSTEMS, NON-DESTRUCTIVE AUTOMATIC CONTROL SYSTEMS, ADAPTIVE PROCESSING MACHINES (grinding, polishing, deburring, welding, etc…),HIGH SPEED ROBOTIZED MEASUREMENT, ASSOCIATED WITH AI FOR AUTOMATIC REAL TIME DECISION MAKING.

Portable 3D measurement system designed by TPSH:

> Locate, detect, dimension, automatically sanction; rivets and all fuselage defects aircraft with the McGUN3D.

SWIR – SWAP – SMART cameras, designed by TPSH:

> Follow your molten pool (welding, Manufacturing additive) in real time with our infrared SWIR camera TCAM 128-65.

Machine vision system associated with image processing ranges, developed, coded by

our teams (neural networks, deep learning):

> Control and measure your parts with our heads intelligent 2D/3D very high speed measurement with robots or cobots.

Vision technologies at the service of automatic transportable inspection developed by TPSH:

> Get an automatic inspection workbench for quality inspection, easily transportable and versatile.

Robotic cells made up of our technologies,designed and realized by our teams:

> Secure your environment with our robotic cells control.

Secure your environment with our robotic cells control:

> Bring the robotic technology automatic adaptative polishing in your factories.

Our software – Human – Machine – Interface, developed by TPSH:

> All our applications are supplied with our HMIs to supervise the cycles and the processes in automatic and real time.

If you would like more technical information about our products, please contact us:by mail at: info@tpsh.fr or by phone at: +33 (0)1 69 11 91 91

Download the brochure of our control systems_robotic_automatic